Generator Design & Installation

One of our clients who operate a fleet with dedicated power cars decided to launch a replacement project for their existing generator sets. The sets in situ had been installed and commissioned in 1997 when the vehicles were first put into service.

The existing units had been partially overhauled several times since original fitment but were display faults common with high “mileage” and use. Non-serviceable components were beginning to reach the limits of wear and tolerances and spare parts were becoming increasingly difficult to source due to obsolescence.

We were asked to design a new system which would be more fuel efficient, reliable and also integrate more modern, safer fire suppression systems. Part of our project brief was also to “future proof” the power requirements of the fleet to ensure future projects (e.g. HVAC system developments) could be accommodated within the output of the newly installed system. Assenta Rail evaluated various options which would fulfil the requirements of our brief and selected generators which would achieve comparable fuel usage to the existing generator sets but which were considerably more powerful.

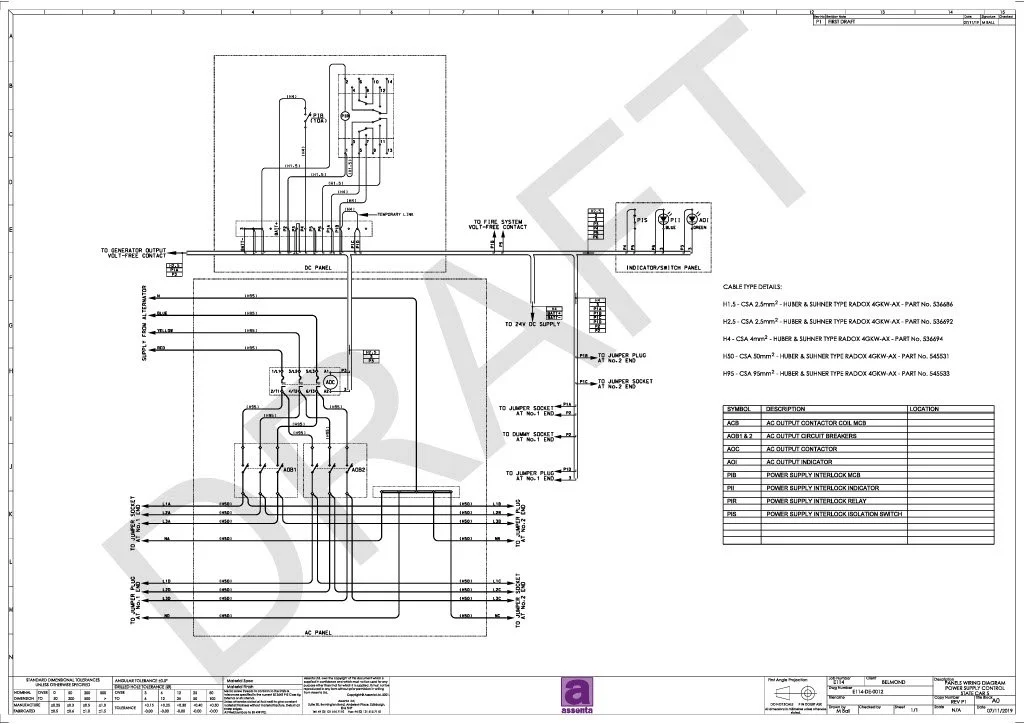

Assenta Rail produced in-house all mechanical, electrical and structural drawings to support the installation of the generators. We designed and installed a new down train mains contactor switching system to ensure that it would be compatible with future down train wiring modifications to accommodate future upgrade projects.

Significant focus was placed on enhancing existing safety measures. We designed the system to be compliant with Railway Group Standards and align the fire safety measures of the current on-board fire system with the new Generator sets incorporating features such as: emergency stop system, down train mains interlock system, louvered vent fresh air intake system, fire suppression system, fire activated engine stop system and fire system indication lighting.

The enhanced fire safety measures (e.g. automatic engine shutdown) reduce the likelihood of a fire on the fleet. The fire suppression system Assenta Rail developed and the use of compliant materials during the installation was done with the focus on reducing the impact and risk to life should a fire occur by mitigating the impact that any fire may cause.

By enhancing exhaust emission reduction we were also able to deliver an increase in safety for personnel operating in the vicinity of the generators by reducing their exposure to harmful gasses.

By installing a more modern generator system on-board the fleet we were able to considerably increase reliability for our client as well as allowing future projects to be more viable due to increased power output. All whilst delivery significant safety benefits and reducing risk to both personnel and passengers alike.